Our sugar bush is located on the property where we live. Our shop is inside the first, gray pole barn behind our home. We began our business in 1998 and currently have approximately 2,200 taps each year.

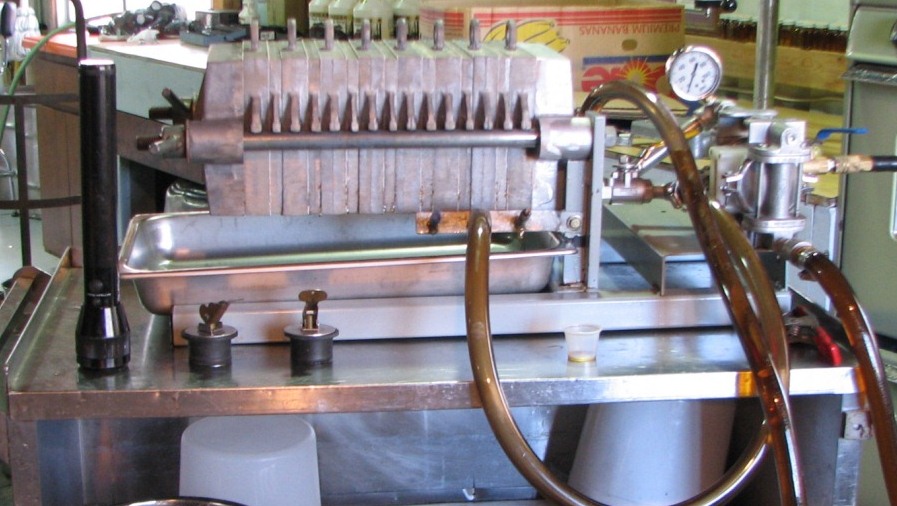

The picture on the left is Chad, our bottling supervisor, bottling syrup in our

sugar house. |

|